Seam tape plays a crucial role in the functionality of outdoor garments and workwear. However, have you encountered any challenges with it? Issues such as wrinkles on the fabric surface after the tape is applied, peeling of the seam tape after washing, or subpar waterproof performance at the seams? These problems typically stem from the type of tape used and the application process. Today, let's explore ways to address these issues.

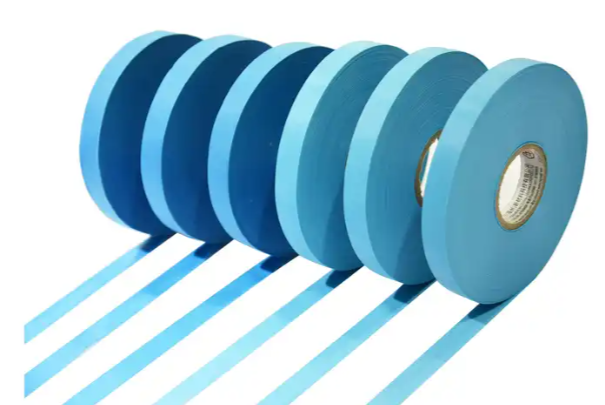

There are many different kinds of seam tapes. Different seam tapes should be used in the different fabrics.

1.Fabric with PVC/PU coating or membrane

As the above fabrics, we can used the PU tape or Semi-PU tape. Semi-PU tape is mixed the PVC and PU material. The PU tape is 100% PU material and more Eco-friendly than Semi- PU tape. So we suggest to use the PU tape and most of clients choose the PU tape. This tape is used in the normal rainwear.

Regarding the color of the tape, the normal colors are transparent, semi-transparent, white and black. If the membrane is allover print, there will be the same overall print on the tape to match the fabric.

There are different thickness here, 0.08mm, 0.10mm and 0.12mm. For example, the fabric 300D oxford with PU coating, it is better to use the 0.10mm PU tape. If the 210T polyester or nylon fabric, the suitable tape is 0.08mm. In general, thicker tape should be used for the thicker fabric and thinner tape should be used for the thinner fabric. This can make the fabric more flatness and fastness.

2.Bonded fabric: The fabrics bonded with mesh, tricot or fleece in back side

As the above fabric, we suggest the bonded tape. It means PU tape bonded with tricot. The tricot color could be same with the fabric, but need MOQ. Which should be checked then. Bonded tape is used in the high-quality outdoor garment (climbing wear, ski suits, diving suits etc.).

Normal colors of the bonded tape are pure black, gray, pure gray and white. The bonded tape is thicker than PU tape. The thickness are 0.3mm and 0.5mm.

3.Non-woven fabric

As the above fabric, we suggest the non-woven tape. Most of the non-woven fabric is used for the medical protective clothing. The advantage of the non-woven tape is stable performance and the soft hand-feeling. After COVID-19, this tape is more and more import for the medical.

The colors of non-woven tape include white, sky blue, orange and green. And the thickness includes 0.1mm 0.12mm 0.16mm.

4.How to control seam tape quality in production

Therefore, various tapes should be applied to different types of fabrics. But the question remains: how can we ensure their durability during the production process?

★The appropriate fabric should be evaluated by the tape manufacturer to determine the suitable tape type and thickness. They apply the tape to a fabric sample for testing, assessing factors such as wash durability, adhesion, and waterproof qualities. Following these tests, the lab provides crucial data, including the recommended temperature, pressure, and application time, which garment factories must adhere to during production.

★The garment factory produces a sample garment with seam tape based on the provided data, followed by testing the fastness after washing. Even if the results appear satisfactory, the sample is still sent to the seam tape manufacturer for further testing using professional laboratory equipment to ensure reconfirmation.

★If the results are not satisfactory, the operational data must be refined until everything is correct. Once achieved, this data should be established as a standard and followed strictly.

★Once the ready-made garment is available, it is essential to send it to the seam tape manufacturer for testing. If it passes the test, bulk production should proceed without any issues.

With above process, we can control the seam tape quality in good condition.

The seam taping process is crucial for functional clothing. If the correct tape is chosen and the proper technique is applied, it can make the fabric smooth and enhance its waterproof performance. Conversely, incorrect application can result in the loss of the fabric's waterproof function. Additionally, improper operational data can cause the fabric to wrinkle and appear unsightly.

In addition to the points mentioned, there are several other important aspects to consider. With 16 years of experience in functional clothing for workwear and outdoor garments, we are delighted to share our insights and lessons learned with you. Feel free to reach out to us for any questions regarding seam taping or to request free samples. Thank you!

Post time: Feb-10-2025